Non-chemical water treatment units for industry EZV, EZV T, M, MT, C, A

Introduction

This manual is intended for designers of warm water (WW) systems, warm-water, hot-water, and steam heating systems, process equipment, saunas, our sellers and agents, and all those who are interested in non-chemical water treatment. It contains a brief description of our individual products, technical engineering data, and practical recommendations concerning the use of this new ecological low-consumption physical technique of water treatment by EZV units and their accessories. The recommendations are based on practical experience with the use of EZV units which were launched in 1993. Owing to continuous development of and improvements in our products, we would appreciate your reporting us any comments, requirements, recommendations and/or proposals that can help us improve the existing technology and/or adjust it to your needs. We will be pleased to answer any inquiries about applications which are not described in this manual and/or other related issues.

Hard water

Water used in various fields of economy and households contains a certain amount of dissolved minerals, salts, and ot her substances. The so-called water hardness depends on the volume of individual elements organisms as well as for plants, however, their precipitation from water causes serious problems due to solid incrustations in water pipings, warmwater systems, laundries, refrigerating systems, etc. Incrustations are formed mainly due to heating hard water, which results in reduced piping diameter, impeded heat flow, and subsequently, higher power losses and reduced life of incrusted systems. There are several methods and techniques of avoiding and/or reducing incrustations. They can be divided according to their effects upon treated water:

her substances. The so-called water hardness depends on the volume of individual elements organisms as well as for plants, however, their precipitation from water causes serious problems due to solid incrustations in water pipings, warmwater systems, laundries, refrigerating systems, etc. Incrustations are formed mainly due to heating hard water, which results in reduced piping diameter, impeded heat flow, and subsequently, higher power losses and reduced life of incrusted systems. There are several methods and techniques of avoiding and/or reducing incrustations. They can be divided according to their effects upon treated water:

a) chemical

b) electrostatic

c) magnetic

The EZV units make use of the magnetic principle, including the microcomputer systems. The following Figure illustrates a piping prior to and after six-week treatment by an EZV 25 unit. Before treatment After six weeks of treatment

EZV water treatment units

Six series of our EZV water treatment units are produced at present, including: uncontrolled units, EZV..., twolevel control units EZV...T, manual control units EZV...M, two-level manual control units EZV...MT, and automatic control units EZV...A. The EZV units are microcomputer-based. Making use of an apropirate algorythm and stored data, the microcomputer generates a highly non-periodic output signal. The signal is amplified in an output stage, and passed to a coil at the treated water piping. Here, it generates a dynamic pulse electromagnetic field. The field affects water flowing through the piping, and distorts the bond of incrusted substances to water molecules. Water treated in this way is unable to form solid incrustations for some time (about 72 hours, depending on specific conditions). Moreover, it dissolves the existing scale. Our digital units provide a non-periodic output signal (which is difficult to obtain in an analog system) important for maximum water treatment efficiency- Moreover, it ensures a long-term (service life of 20 years) and temperature stability (standard working temperature ranges from 0°C through 40°C) of magnetic field parameters, simple and precise processing of signals from flow meters, and simple communication with a master computer (e.g., an RS 485 interface). The units are provided with an independent automatic check circuit, designed to check the presence of an output signal, and subsequent reactivation of the microcomputer. As a result, the EZV units are resistant against supply voltage oscillations, external interferences, etc. They are embedded in plastic boxes, with the electronic part being sealed with a electronic hard water treatment special substance protecting it form undesired environmental effects, such as moisture, insects, etc. The units are dimensioned for supply voltage 220-230V, however, they can also be adapted to other supply voltages (110V, 24V, battery supply, back-up power supply, etc.). The units are designed as Class II consumers, with output circuits being galvanically separated from the supply mains. Output signal voltage and current values are lower than the maximum admissible values of the so-called safe voltage and current. Therefore, they can in no way jeopardise human health. Power consumption of these units is very low, and ranges from 3 to 20 W at 230V mains supply, depending on a specific type. The components of the units have been delivered by suppliers meeting the ISO 9001 conditions. Each unit were tested on a test-board for 150 hours as a minimum. The guarantee period is three years, and the service life 20 years. Guarantee and post-guarantee services are provided by the manufacturer - EZV Ltd. The conductor used as a coil which generates a magnetic field, has been insulated in the manufacturer s factory. The insulation is dimensioned for heat stress up to 70°C. When a unit is used for water treatment in systems featuring higher working temperature (hot-water heating systems), conductors are provided with insulation for the maximum heat stress of 180°C. Therefore, it is necessary to specify the maximum temperature of the piping which the water treatment unit will be applied to.

Uncontrolled devices EZV 10 to EZV 65

This series is designed for minor applications (from 3/8"to 2,5") in systems with minimum flow rate changes. The units are manufactured for optimum flow rates indicated in the Table. The manufacturer can deliver a unit with a flow rate range shifted either to higher or reduced flow rates, depending on a specific application. It is recommended to consult such modifications in advance, with indicating the required flow rate range in unit specifications. These units are primarily used for water treatment in family houses, bakeries, laundries, steam boilers, ironing and steaming devices, partly in WW circulation pipings, press cooling systems, milk pasteurizers, small steam boilers, small flow heaters.

This series is designed for minor applications (from 3/8"to 2,5") in systems with minimum flow rate changes. The units are manufactured for optimum flow rates indicated in the Table. The manufacturer can deliver a unit with a flow rate range shifted either to higher or reduced flow rates, depending on a specific application. It is recommended to consult such modifications in advance, with indicating the required flow rate range in unit specifications. These units are primarily used for water treatment in family houses, bakeries, laundries, steam boilers, ironing and steaming devices, partly in WW circulation pipings, press cooling systems, milk pasteurizers, small steam boilers, small flow heaters.

Two-level control units EZV 25 T to EZV 65 T

These units are designed for applications with regular and relatively large flow rate changes (changes exceeding the capacity of the EZV...series). The regularity of changes is derived either from time (e.g. day/night, shift beginning/end, etc.), or from the operation of other devices (e.g. circulating pumps, etc.). The series allows for two-level control by switching an auxiliary contact on the unit. Switching can be operated by a timer (can by included in a delivery) with a 24 or 168 hour switching cycle, by an auxiliary contact of a contactor which switches a circulating pump, by a boiler room or a technological process control system, or by some other device. In the case of control system operation, an auxiliary contact may be replaced with an appropriate interface such as RS 485. Generally, a switching device is required to switch 10mA/25V; max. electronic hard water treatment distance of 100 m. If no switching device is connected, or the auxiliary contact is disconnected, the unit is switched over to flow rate range 1 - see the Table below. The connector used for connecting a switching device is supplied with 12V/10 mA, which may be used, for instance, for supplying a modified timer (delivered by EZV Ltd.). Applications: heat-exchanger plants, common WW treatment in blocks of flats, hotels, warm-water heating systems with circulating pump regulation, some technological equipment, etc.

EZV...series). The regularity of changes is derived either from time (e.g. day/night, shift beginning/end, etc.), or from the operation of other devices (e.g. circulating pumps, etc.). The series allows for two-level control by switching an auxiliary contact on the unit. Switching can be operated by a timer (can by included in a delivery) with a 24 or 168 hour switching cycle, by an auxiliary contact of a contactor which switches a circulating pump, by a boiler room or a technological process control system, or by some other device. In the case of control system operation, an auxiliary contact may be replaced with an appropriate interface such as RS 485. Generally, a switching device is required to switch 10mA/25V; max. electronic hard water treatment distance of 100 m. If no switching device is connected, or the auxiliary contact is disconnected, the unit is switched over to flow rate range 1 - see the Table below. The connector used for connecting a switching device is supplied with 12V/10 mA, which may be used, for instance, for supplying a modified timer (delivered by EZV Ltd.). Applications: heat-exchanger plants, common WW treatment in blocks of flats, hotels, warm-water heating systems with circulating pump regulation, some technological equipment, etc.

Manual control units EZV 50 M to EZV 500 M

This  series of water treatment units makes it possible to change output signal parameters within a wide range by means of a switch, and thus to optimize the effects of a unit in a wide range of flow rates with regard to treated water properties. Optimization itself may be achieved by long-term observation of effects relative to the level selected, or by suitable water parameter measurements prior to and following the process of treatment, depending on the adjusted values (e.g. conductivity, pH, etc.). The enclosure class for units of this series is IP44. The units are provided with acoustic indicators (open coil circuit or disconnected coil) and relais contacts which are closed when operating correctly (this feature can be used for remote signalling). Relais contact capacity is 1A/125V, however 25 W max. Applications: larger systems (above 2“) with forced circulation, warm-water and hot-water heating systems, steam boilers (water pre-treatment), WW circulation, large swimming pools, process equipment (compressor cooling, oil coolers, etc.) .

series of water treatment units makes it possible to change output signal parameters within a wide range by means of a switch, and thus to optimize the effects of a unit in a wide range of flow rates with regard to treated water properties. Optimization itself may be achieved by long-term observation of effects relative to the level selected, or by suitable water parameter measurements prior to and following the process of treatment, depending on the adjusted values (e.g. conductivity, pH, etc.). The enclosure class for units of this series is IP44. The units are provided with acoustic indicators (open coil circuit or disconnected coil) and relais contacts which are closed when operating correctly (this feature can be used for remote signalling). Relais contact capacity is 1A/125V, however 25 W max. Applications: larger systems (above 2“) with forced circulation, warm-water and hot-water heating systems, steam boilers (water pre-treatment), WW circulation, large swimming pools, process equipment (compressor cooling, oil coolers, etc.) .

Cyclically control units EZV 50 C to EZV 500 C

The devices of the series have been designed for the water treatment of the closed systems in which the flow values do not h ave to be constant but it can vary (for example during regulation by means of multidirectional mixing valves). The devices exploit time invariance of the physical water treatment (approximately 72 hours) and with particular and appropriate period the devices change the parameters of output signal cyclically covering the wide range of flows of the closed systems. Contrary to the EZV... M devices, it is not necessary to implement additional optimalization of the proper degree setting when using the EZV... C devices. The optimal parameters of the electronic hard water treatment output signal are inherent in the output signal for the particular parameter and the output signal varies constantly in the wide range with the specific and appropriate period. The devices are equipped by the acoustic signalisation and auxiliary relay – the same data refer to the EZV...M devices.

ave to be constant but it can vary (for example during regulation by means of multidirectional mixing valves). The devices exploit time invariance of the physical water treatment (approximately 72 hours) and with particular and appropriate period the devices change the parameters of output signal cyclically covering the wide range of flows of the closed systems. Contrary to the EZV... M devices, it is not necessary to implement additional optimalization of the proper degree setting when using the EZV... C devices. The optimal parameters of the electronic hard water treatment output signal are inherent in the output signal for the particular parameter and the output signal varies constantly in the wide range with the specific and appropriate period. The devices are equipped by the acoustic signalisation and auxiliary relay – the same data refer to the EZV...M devices.

Two-level control and manual presetting units EZV...MT

These units are designed for larger systems (above 2“) with regular and relatively frequent flow rate alterations between considerably diffe rent values. The regularity, or the dependence of these alterations, may be, similarly to the EZV...T series, derived from time, switching of some other device, or may be given by a control system. The switch for flow rate range1 is used to preset an appropriate level corresponding to an open auxiliary contact, the switch for range 2 is used to preset a level corresponding to flow rate range 2 (with the auxiliary contact closed). By connecting, for instance, a timer it is possible, depending on time, to switch over between two preset flow rate values. Requirements on a switching device capacity are similar to those of the EZV...T series, i.e., 10mA/25V. When switching is operated by a control system, an auxiliary contact may be replaced by a suitable computer interface. The units are fitted with an acoustic indicator, an auxiliary relais (the same data as specified for the EZV...M series), and auxiliary AC voltage 12V/10mA (at the connector reserved for connecting a switching device). The voltage is used, for instance, for supplying a modified timer (delivered by Applications: heat-exchanger plants, WW treatment in larger buildings (dormitories, barracks, etc.), warm-water and hotwater heating systems with circulating pump regulation, larger process equipment, etc.

rent values. The regularity, or the dependence of these alterations, may be, similarly to the EZV...T series, derived from time, switching of some other device, or may be given by a control system. The switch for flow rate range1 is used to preset an appropriate level corresponding to an open auxiliary contact, the switch for range 2 is used to preset a level corresponding to flow rate range 2 (with the auxiliary contact closed). By connecting, for instance, a timer it is possible, depending on time, to switch over between two preset flow rate values. Requirements on a switching device capacity are similar to those of the EZV...T series, i.e., 10mA/25V. When switching is operated by a control system, an auxiliary contact may be replaced by a suitable computer interface. The units are fitted with an acoustic indicator, an auxiliary relais (the same data as specified for the EZV...M series), and auxiliary AC voltage 12V/10mA (at the connector reserved for connecting a switching device). The voltage is used, for instance, for supplying a modified timer (delivered by Applications: heat-exchanger plants, WW treatment in larger buildings (dormitories, barracks, etc.), warm-water and hotwater heating systems with circulating pump regulation, larger process equipment, etc.

Automatic control units EZV 50 A to EZV 500 A

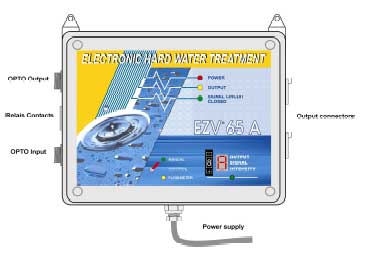

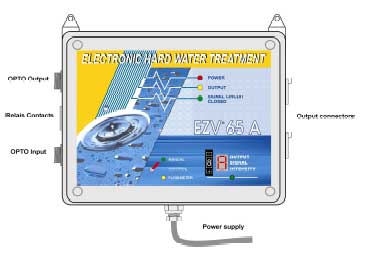

These units are designed for systems with large and irregular flow rate alterations. They require information of a flow rate, i.e., the system must incorporate a flow meter provided with an electric output or with the possibility to connect an appropriate sensor. These units are fitted with controls (only accessible to servicemen) which make it possible to optimize automatically adjusted unit parameters relative to a flow rate and to treated water parameters. Analogically to the EZV...M and EZV...MT series> units, they are provided with a signalling unit and an auxiliary relais. The arrangement of connector outlets and contact capacities are the same. A flow meter is connected via another connector. The Figure illustrates the connection of most frequently used sensors OPTO 1,2, OPTO EZV 1,2 or REED sensors.

These units are designed for systems with large and irregular flow rate alterations. They require information of a flow rate, i.e., the system must incorporate a flow meter provided with an electric output or with the possibility to connect an appropriate sensor. These units are fitted with controls (only accessible to servicemen) which make it possible to optimize automatically adjusted unit parameters relative to a flow rate and to treated water parameters. Analogically to the EZV...M and EZV...MT series> units, they are provided with a signalling unit and an auxiliary relais. The arrangement of connector outlets and contact capacities are the same. A flow meter is connected via another connector. The Figure illustrates the connection of most frequently used sensors OPTO 1,2, OPTO EZV 1,2 or REED sensors.

Applications: WW treatment systems - treatment of cold water supply, treatment of supply water for steam boilers, water treatment for large plants - heating plants, water treatment for applications strictly requiring continuous supplies of highquality water, gravity water systems, etc.

her substances. The so-called water hardness depends on the volume of individual elements organisms as well as for plants, however, their precipitation from water causes serious problems due to solid incrustations in water pipings, warmwater systems, laundries, refrigerating systems, etc. Incrustations are formed mainly due to heating hard water, which results in reduced piping diameter, impeded heat flow, and subsequently, higher power losses and reduced life of incrusted systems. There are several methods and techniques of avoiding and/or reducing incrustations. They can be divided according to their effects upon treated water:

her substances. The so-called water hardness depends on the volume of individual elements organisms as well as for plants, however, their precipitation from water causes serious problems due to solid incrustations in water pipings, warmwater systems, laundries, refrigerating systems, etc. Incrustations are formed mainly due to heating hard water, which results in reduced piping diameter, impeded heat flow, and subsequently, higher power losses and reduced life of incrusted systems. There are several methods and techniques of avoiding and/or reducing incrustations. They can be divided according to their effects upon treated water: This series is designed for minor applications (from 3/8"to 2,5") in systems with minimum flow rate changes. The units are manufactured for optimum flow rates indicated in the Table. The manufacturer can deliver a unit with a flow rate range shifted either to higher or reduced flow rates, depending on a specific application. It is recommended to consult such modifications in advance, with indicating the required flow rate range in unit specifications. These units are primarily used for water treatment in family houses, bakeries, laundries, steam boilers, ironing and steaming devices, partly in WW circulation pipings, press cooling systems, milk pasteurizers, small steam boilers, small flow heaters.

This series is designed for minor applications (from 3/8"to 2,5") in systems with minimum flow rate changes. The units are manufactured for optimum flow rates indicated in the Table. The manufacturer can deliver a unit with a flow rate range shifted either to higher or reduced flow rates, depending on a specific application. It is recommended to consult such modifications in advance, with indicating the required flow rate range in unit specifications. These units are primarily used for water treatment in family houses, bakeries, laundries, steam boilers, ironing and steaming devices, partly in WW circulation pipings, press cooling systems, milk pasteurizers, small steam boilers, small flow heaters. EZV...series). The regularity of changes is derived either from time (e.g. day/night, shift beginning/end, etc.), or from the operation of other devices (e.g. circulating pumps, etc.). The series allows for two-level control by switching an auxiliary contact on the unit. Switching can be operated by a timer (can by included in a delivery) with a 24 or 168 hour switching cycle, by an auxiliary contact of a contactor which switches a circulating pump, by a boiler room or a technological process control system, or by some other device. In the case of control system operation, an auxiliary contact may be replaced with an appropriate interface such as RS 485. Generally, a switching device is required to switch 10mA/25V; max. electronic hard water treatment distance of 100 m. If no switching device is connected, or the auxiliary contact is disconnected, the unit is switched over to flow rate range 1 - see the Table below. The connector used for connecting a switching device is supplied with 12V/10 mA, which may be used, for instance, for supplying a modified timer (delivered by EZV Ltd.). Applications: heat-exchanger plants, common WW treatment in blocks of flats, hotels, warm-water heating systems with circulating pump regulation, some technological equipment, etc.

EZV...series). The regularity of changes is derived either from time (e.g. day/night, shift beginning/end, etc.), or from the operation of other devices (e.g. circulating pumps, etc.). The series allows for two-level control by switching an auxiliary contact on the unit. Switching can be operated by a timer (can by included in a delivery) with a 24 or 168 hour switching cycle, by an auxiliary contact of a contactor which switches a circulating pump, by a boiler room or a technological process control system, or by some other device. In the case of control system operation, an auxiliary contact may be replaced with an appropriate interface such as RS 485. Generally, a switching device is required to switch 10mA/25V; max. electronic hard water treatment distance of 100 m. If no switching device is connected, or the auxiliary contact is disconnected, the unit is switched over to flow rate range 1 - see the Table below. The connector used for connecting a switching device is supplied with 12V/10 mA, which may be used, for instance, for supplying a modified timer (delivered by EZV Ltd.). Applications: heat-exchanger plants, common WW treatment in blocks of flats, hotels, warm-water heating systems with circulating pump regulation, some technological equipment, etc. series of water treatment units makes it possible to change output signal parameters within a wide range by means of a switch, and thus to optimize the effects of a unit in a wide range of flow rates with regard to treated water properties. Optimization itself may be achieved by long-term observation of effects relative to the level selected, or by suitable water parameter measurements prior to and following the process of treatment, depending on the adjusted values (e.g. conductivity, pH, etc.). The enclosure class for units of this series is IP44. The units are provided with acoustic indicators (open coil circuit or disconnected coil) and relais contacts which are closed when operating correctly (this feature can be used for remote signalling). Relais contact capacity is 1A/125V, however 25 W max. Applications: larger systems (above 2“) with forced circulation, warm-water and hot-water heating systems, steam boilers (water pre-treatment), WW circulation, large swimming pools, process equipment (compressor cooling, oil coolers, etc.) .

series of water treatment units makes it possible to change output signal parameters within a wide range by means of a switch, and thus to optimize the effects of a unit in a wide range of flow rates with regard to treated water properties. Optimization itself may be achieved by long-term observation of effects relative to the level selected, or by suitable water parameter measurements prior to and following the process of treatment, depending on the adjusted values (e.g. conductivity, pH, etc.). The enclosure class for units of this series is IP44. The units are provided with acoustic indicators (open coil circuit or disconnected coil) and relais contacts which are closed when operating correctly (this feature can be used for remote signalling). Relais contact capacity is 1A/125V, however 25 W max. Applications: larger systems (above 2“) with forced circulation, warm-water and hot-water heating systems, steam boilers (water pre-treatment), WW circulation, large swimming pools, process equipment (compressor cooling, oil coolers, etc.) . ave to be constant but it can vary (for example during regulation by means of multidirectional mixing valves). The devices exploit time invariance of the physical water treatment (approximately 72 hours) and with particular and appropriate period the devices change the parameters of output signal cyclically covering the wide range of flows of the closed systems. Contrary to the EZV... M devices, it is not necessary to implement additional optimalization of the proper degree setting when using the EZV... C devices. The optimal parameters of the electronic hard water treatment output signal are inherent in the output signal for the particular parameter and the output signal varies constantly in the wide range with the specific and appropriate period. The devices are equipped by the acoustic signalisation and auxiliary relay – the same data refer to the EZV...M devices.

ave to be constant but it can vary (for example during regulation by means of multidirectional mixing valves). The devices exploit time invariance of the physical water treatment (approximately 72 hours) and with particular and appropriate period the devices change the parameters of output signal cyclically covering the wide range of flows of the closed systems. Contrary to the EZV... M devices, it is not necessary to implement additional optimalization of the proper degree setting when using the EZV... C devices. The optimal parameters of the electronic hard water treatment output signal are inherent in the output signal for the particular parameter and the output signal varies constantly in the wide range with the specific and appropriate period. The devices are equipped by the acoustic signalisation and auxiliary relay – the same data refer to the EZV...M devices. rent values. The regularity, or the dependence of these alterations, may be, similarly to the EZV...T series, derived from time, switching of some other device, or may be given by a control system. The switch for flow rate range1 is used to preset an appropriate level corresponding to an open auxiliary contact, the switch for range 2 is used to preset a level corresponding to flow rate range 2 (with the auxiliary contact closed). By connecting, for instance, a timer it is possible, depending on time, to switch over between two preset flow rate values. Requirements on a switching device capacity are similar to those of the EZV...T series, i.e., 10mA/25V. When switching is operated by a control system, an auxiliary contact may be replaced by a suitable computer interface. The units are fitted with an acoustic indicator, an auxiliary relais (the same data as specified for the EZV...M series), and auxiliary AC voltage 12V/10mA (at the connector reserved for connecting a switching device). The voltage is used, for instance, for supplying a modified timer (delivered by Applications: heat-exchanger plants, WW treatment in larger buildings (dormitories, barracks, etc.), warm-water and hotwater heating systems with circulating pump regulation, larger process equipment, etc.

rent values. The regularity, or the dependence of these alterations, may be, similarly to the EZV...T series, derived from time, switching of some other device, or may be given by a control system. The switch for flow rate range1 is used to preset an appropriate level corresponding to an open auxiliary contact, the switch for range 2 is used to preset a level corresponding to flow rate range 2 (with the auxiliary contact closed). By connecting, for instance, a timer it is possible, depending on time, to switch over between two preset flow rate values. Requirements on a switching device capacity are similar to those of the EZV...T series, i.e., 10mA/25V. When switching is operated by a control system, an auxiliary contact may be replaced by a suitable computer interface. The units are fitted with an acoustic indicator, an auxiliary relais (the same data as specified for the EZV...M series), and auxiliary AC voltage 12V/10mA (at the connector reserved for connecting a switching device). The voltage is used, for instance, for supplying a modified timer (delivered by Applications: heat-exchanger plants, WW treatment in larger buildings (dormitories, barracks, etc.), warm-water and hotwater heating systems with circulating pump regulation, larger process equipment, etc. These units are designed for systems with large and irregular flow rate alterations. They require information of a flow rate, i.e., the system must incorporate a flow meter provided with an electric output or with the possibility to connect an appropriate sensor. These units are fitted with controls (only accessible to servicemen) which make it possible to optimize automatically adjusted unit parameters relative to a flow rate and to treated water parameters. Analogically to the EZV...M and EZV...MT series> units, they are provided with a signalling unit and an auxiliary relais. The arrangement of connector outlets and contact capacities are the same. A flow meter is connected via another connector. The Figure illustrates the connection of most frequently used sensors OPTO 1,2, OPTO EZV 1,2 or REED sensors.

These units are designed for systems with large and irregular flow rate alterations. They require information of a flow rate, i.e., the system must incorporate a flow meter provided with an electric output or with the possibility to connect an appropriate sensor. These units are fitted with controls (only accessible to servicemen) which make it possible to optimize automatically adjusted unit parameters relative to a flow rate and to treated water parameters. Analogically to the EZV...M and EZV...MT series> units, they are provided with a signalling unit and an auxiliary relais. The arrangement of connector outlets and contact capacities are the same. A flow meter is connected via another connector. The Figure illustrates the connection of most frequently used sensors OPTO 1,2, OPTO EZV 1,2 or REED sensors.